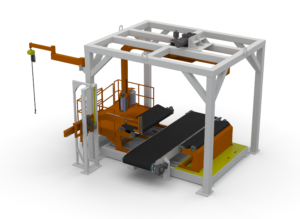

Parent Roll Load & Unload Systems

Description

Automatic Handling’s Parent Roll Load & Unload System automates the process of inserting and removing core plugs from cores, and loading parent rolls into a tissue converting line.

This system not only creates a safer working environment for your staff but allows for the efficient introduction of raw materials into the manufacturing process. Spent cores are automatically processed and reject cores can be removed from the line at any time.

Applicable Industries:

Tissue & Towel

System Highlights

- Automatic overhead delivery system

- Safer work environment

- Custom Programmed to keep pace with your production operations

- Spent core and core plug management

- Automatic removal of core plugs

How does the system work?

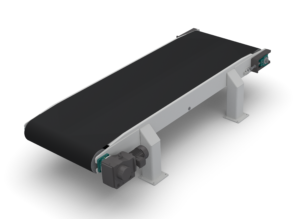

A clamp truck or Automatic Guided Vehicle (AGV) introduces parent rolls into the system’s infeed conveyor. Rolls are transported onto the transfer cart and delivered to the core plugging towers. Here, the machine automatically inserts the customer-supplied core plugs into the parent roll’s core, and the plugging towers lift the parent roll off the transfer cart. After the car moves away, an operator is allowed into the secured zone to prepare the parent roll for the converting line.

The automated overhead delivery crane lifts the parent roll out of the plugging towers and delivers them to the unwind stand of the converting machine. The delivery crane then picks up the spent roll at the same station and gives it to the spent roll cart and awaits the next sequence. The spent roll cart traverses into the plugging towers where the core plugs are automatically removed from the spent roll for reintroduction to the next parent roll. Next, the spent roll arrives at the roll pick-up location for clamp truck or AGV interface. The system also removes rejected rolls from the converting line or the plugging towers if an operator uncovers a product concern. Reject rolls transfer to the reject pick-up station for clamp truck or AGV interface. A maintenance crane on the same Automatic Handling provided runway steel moves the entire length of the system.

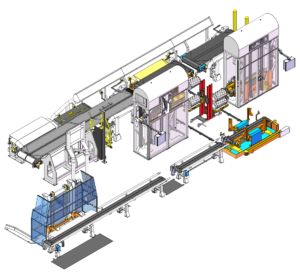

Parent Roll Load & Unload Example

The parent roll load and unload system depicted here includes:

- Turntable for controlling roll wind direction

- Parent roll core plugging and spent roll plug removal

- Interfacing with overhead crane management system

- Automatic core loading into core bin