Recycled Bale Dewiring

Description

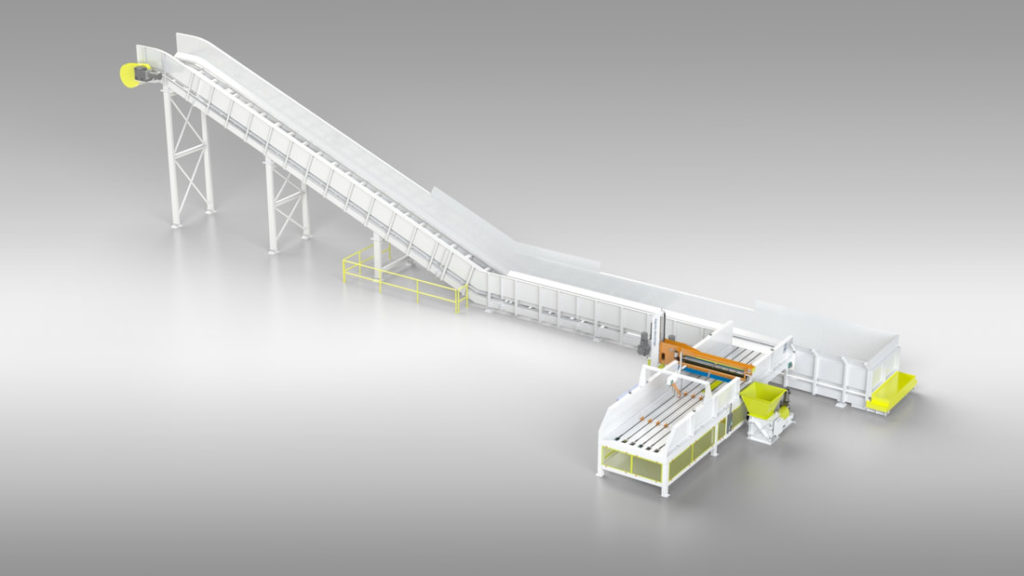

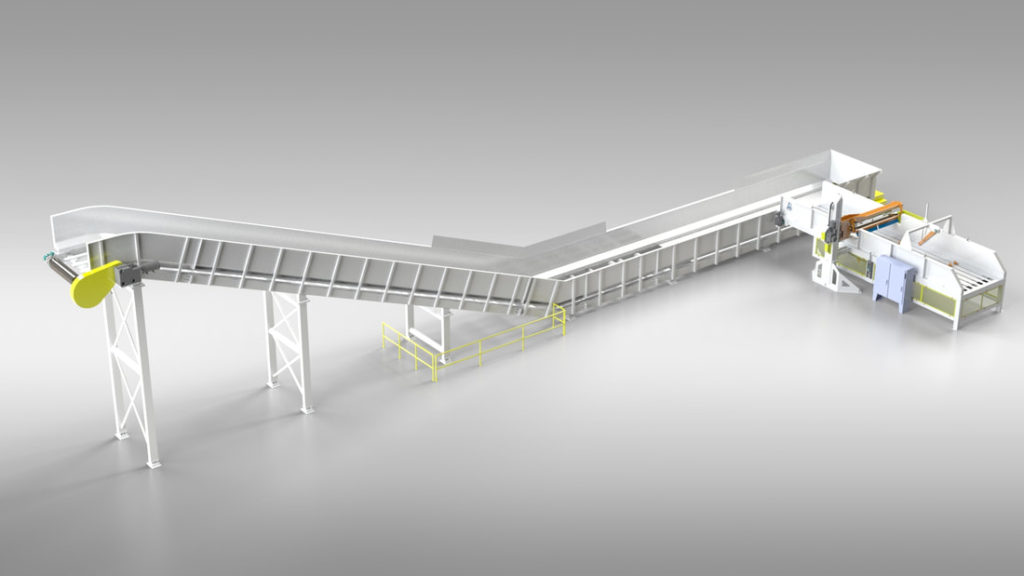

The Automatic Handling Recycled Bale Dewiring unit automates the removal of wires, eliminating the safety hazard around the operator interface, eliminate damage to pulpers and pulper feed conveyors, and reduce maintenance and downtime.

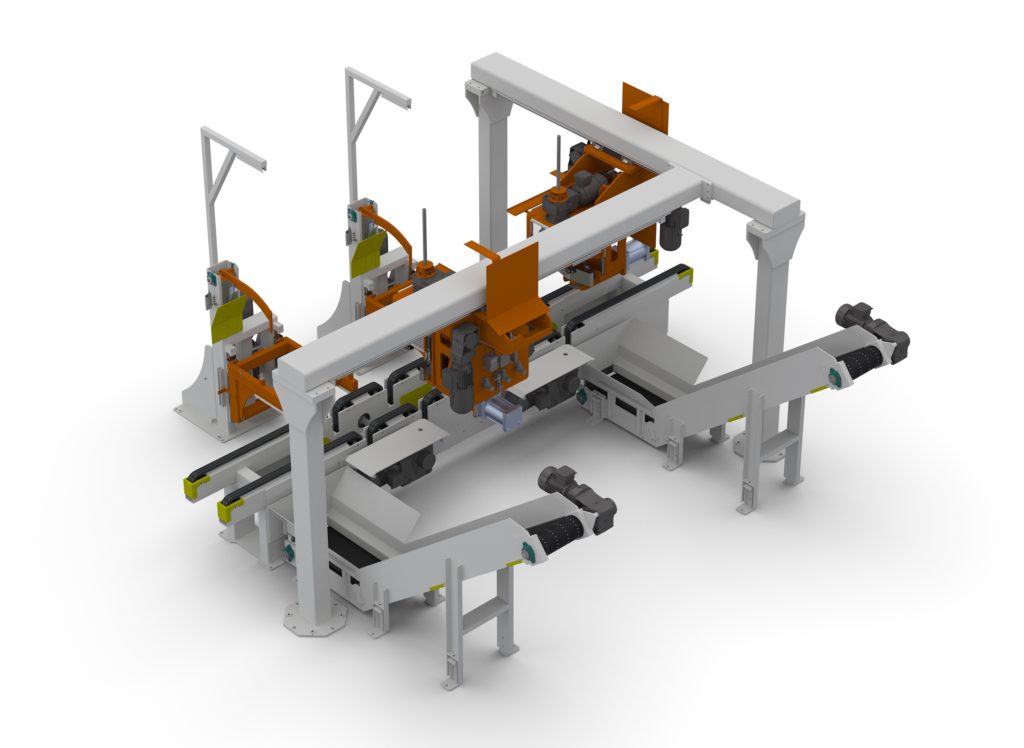

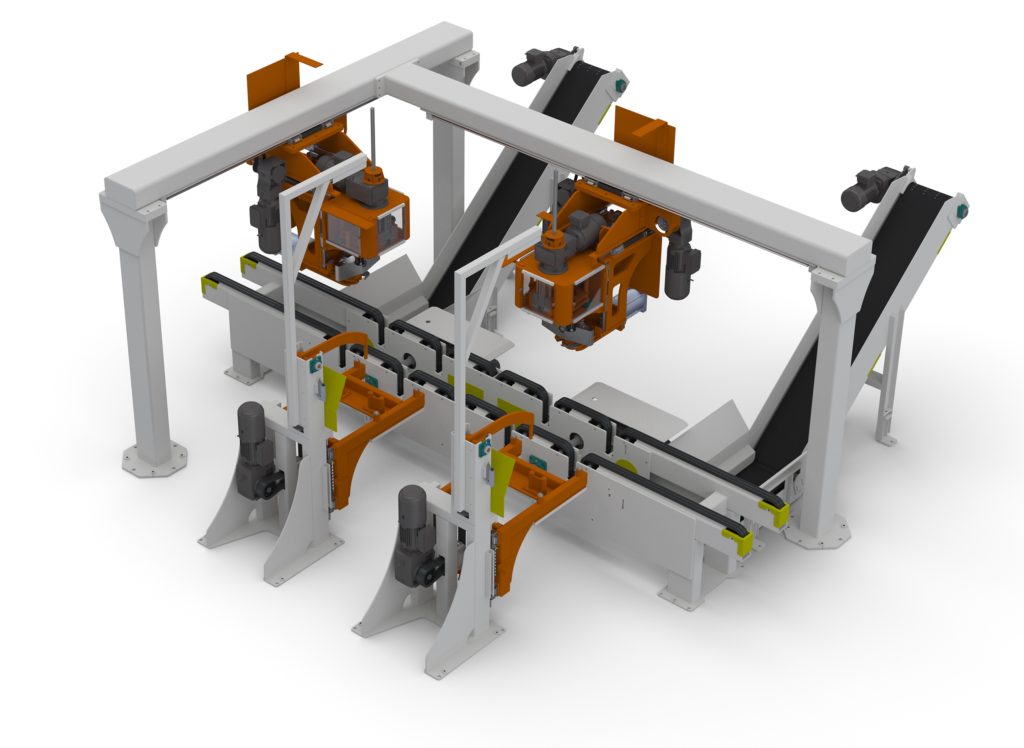

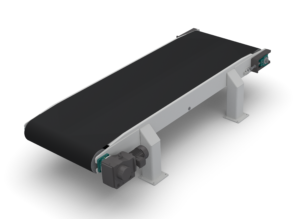

Automate your recycle system by adding an infeed conveyor, pulper feed conveyor, guillotine, bale breaker, and more depending on your operational requirements. This system is also available in a smaller semi-automatic version.

Applicable Industries

Recycling

System Highlights

- 100% of available wires removed

- Eliminates operator contact with wires

- No wires on pulper feed conveyors

- Custom bale-height sensing and arbor adjustment

- Updated diagnostics to help with troubleshooting

- Integrated guarding to protect wires, air line and hoses from damage

- Engineered, manufactured, serviced and supported in the USA

What other benefits does a recycle bale dewiring machine offer?

This system offers a continuous, worry-free solution to remove wires safely from bales, protecting operators from harm. Our Automatic Bale Dewiring unit can be part of a larger automated recycle system that may include an infeed conveyor, pulper feed conveyor, guillotine, bale breaker, etc. or can be delivered as a smaller semi-automatic version. Solutions are customizable for those with a budget, lower volume, space constraints, various bale sizes, or semi-automatic version.

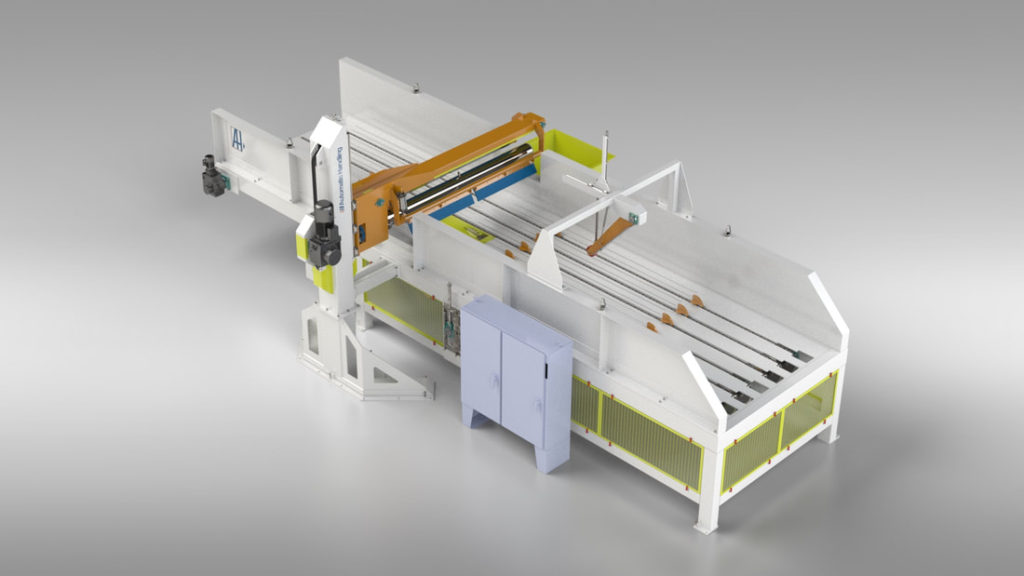

Fully Automatic vs Semi Automatic Bale Handling

The fully automatic dewire machine features a rider roll arm that senses the top profile of the bale.The rider arm is actuated by a deck switch which senses the bale leading edge. The profile is saved by the PLC and is used to adjust the height of the arbor which efficiently and effectively can remove the cut bale wires. The operator’s only job is to load bales, they system does the rest without operator interaction.

By contrast the semi automatic bale dewiring machine, requires the operator to set the bale height because it does not include the rider arm that senses bale height. The arbor height is set above the conveyor deck by control panel or remote control (pendant or wireless). The semi automatic machine is recommended as cost effective solution for lower capacity operations.

Automatic Bale Dewiring Systems

Compression balers can create bales with varied sizes. As a result, Automatic Handling has adapted our dewiring capabilities to automatically detect the size of the bale and fully remove all bale wires prior to processing in the pulper. Dewiring systems present a great upgrade opportunity to improve the safety of your operations.