Roll Handling & Roll Wrapping Systems

Description

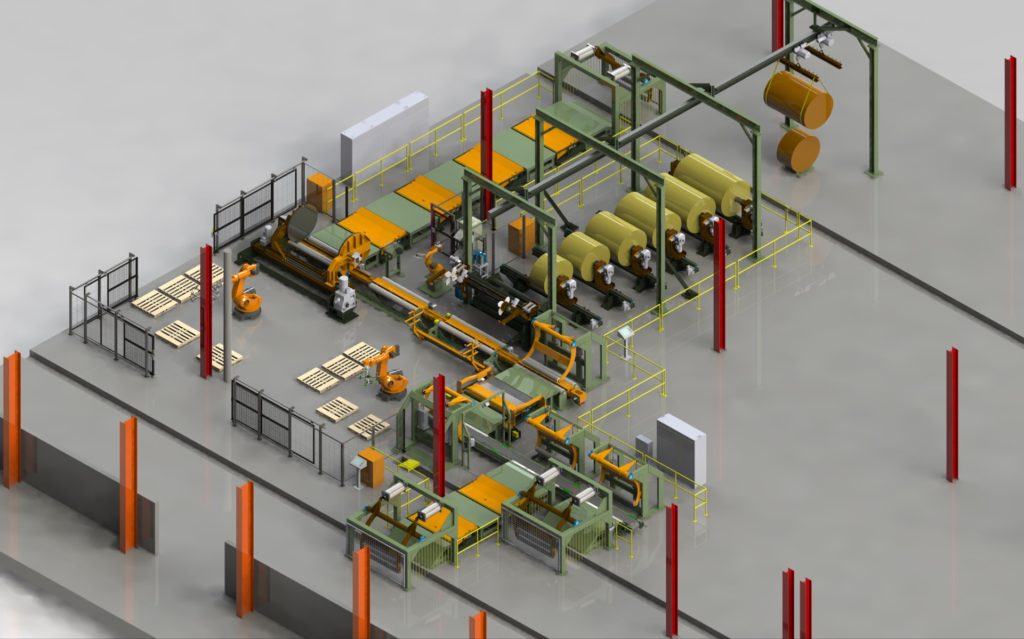

Regardless of the industry, Automatic Handling is equipped to design, build, and automate the movement of material rolls or large production components through the manufacturing process.

Whether transferring or wrapping raw materials or finished goods our team has the capability to meet your toughest challenges head on while improving safety, reliability, and through-put.

Applicable Industries:

System Highlights

- Available for rolls ranging in diameter from 6" to 160"

- Increased protection of raw or finished materials

- Wrapping materials include film or kraft paper

- Optional labeling stations improve efficiency

- Patented Edgegard protects materials in transport

- Patented Heat Seal Technology reduces messes

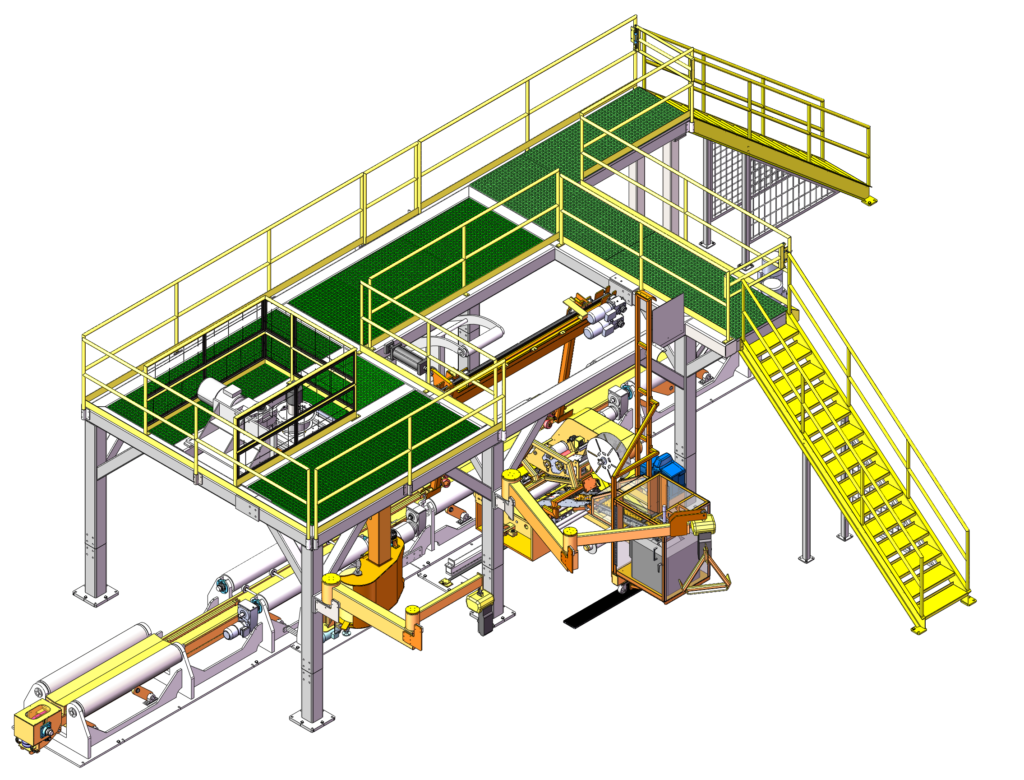

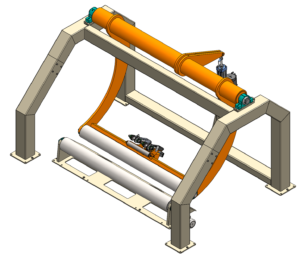

Roll Handling Capabilities

Our experience includes rolls the handling of rolls ranging in diameter from 6” up to 110” with weights ranging from 10,000 to 15,000 lbs. across a variety of industries. If you have something bigger, we are always up for the challenge. Talk to our team about our custom solutions.

Roll Wrapping Capabilities

We have extensive experience wrapping and packaging raw materials with Film or Kraft paper. Film wrapping can be accomplished in a variety of ways from new stations to integrating directly into your existing production line. Our engineers consider a variety of factors to develop a custom solution to optimize your manufacturing operations. Our Roll Wrapping systems have a variety of upgrade options including our Edgegard, patented Heat Seal Technology and Labeling capabilities.What is Edgegard?

Edgegard is a 20-mil thick (thickness based on application) Polyethylene (PE) film material that is applied during the wrapping process and is entirely recyclable with the wrapping film. The patented material was created to take the abuse that the roll ends are subjected to daily as well as maintain package integrity. Stretch film is not new in roll packaging but has received a bad reputation in some applications. The use of low cost or thin films leads to the inevitable problem of the film being torn off the bottom of the roll when palletized.

Add Heat Seal Technology to save on supplies and reduce mess

Our patented Heat Seal Technology can be added to new or existing wrapping equipment. The benefits to your operations include:

- Eliminates the need for glue to seal tail of film to package.

- Proven technology used in multiple existing wrapper upgrades.

- Utilizes (4) heated rollers to melt tail of film to end of wrap cycle.

- Prevents premature unravelling as tail does not release from package (a common issue with glue after extended storage times).

- Does not affect current wrapper cycle time.

- Integrates into existing hold-down roller frame for ease of installation.

- Includes a dedicated electrical panel that is pre-wired at AHI prior to shipping.

- Existing glue system does not need to be removed and can be kept as a backup.

- Ability to use either film attach method from within the HMI screen.

- Critical spare parts stocked by AHI for quick delivery.

- AHI turn-key installation and start-up available for ease of integration.

Stay organized with an optional labeling station

An automatic label applicator can be installed to apply labels to finished materials prior to storage or transport. Our customers count on Automatic Handling’s expertise to optimize their labeling quality with either labeling via a simple mechanical device, a robotic end of arm tooling, or inline radial wrapping labels.Examples of Roll Handling & WRapping Systems We've built

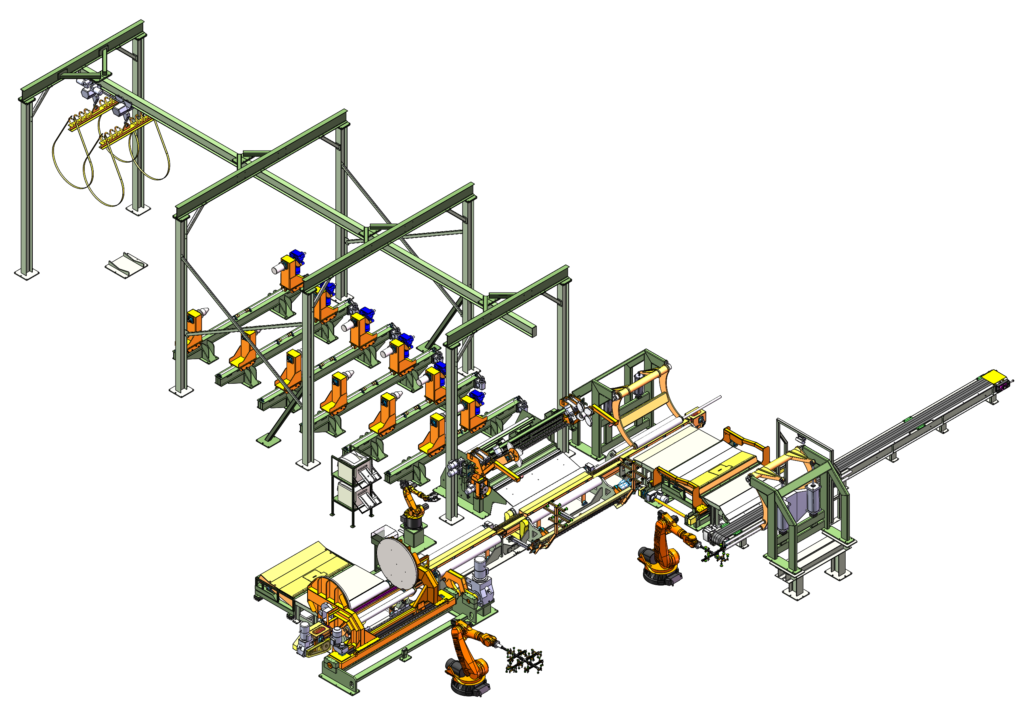

Our custom roll handling and roll wrapping systems can be configured to your specific production needs.

Roll Wrapping Example 1

This kraft roll wrapping system includes:

- Robotic header placement

- Automatic roll measuring and weighing

- Automatic Labeling

- High speed kraft wrapping

- All electric operation, no hydraulics

- Pivoting electronic header press

Roll Wrapping Example 2

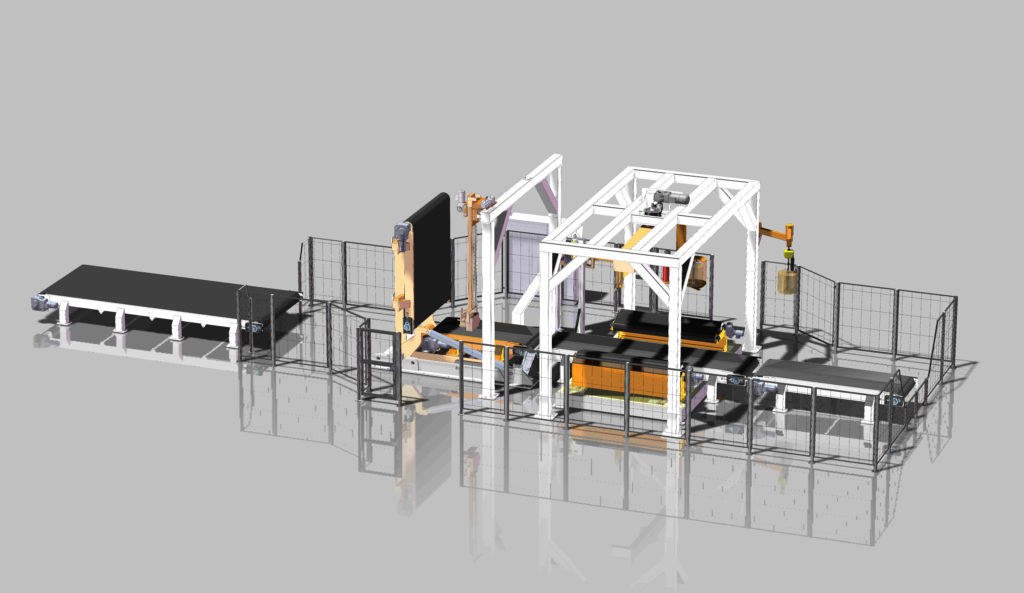

This tissue wrapping system includes:

- Axial (Cocoon) Wrapping

- Automatic labeling

- Electric operation

- Upender to outfeed conveyors

Roll Wrapping Example 3

This kraft roll wrapping system includes:

- Robotic header application

Roll Wrapping Example 4