Core Joining Systems

Description

Reduce your costs and environmental impact with Automatic Handling’s Core Joining System. The Automatic Handling Core Joiner is a fully automatic system for gluing recycled cores into new cores. Custom manufactured to your mills exact requirements, our core joining system allows paper manufacturers to reuse cores of different sizes and grades repeatedly to avoid the high costs of disposal and replacement.

Applicable Industries:

Tissue & Towel

System Highlights

- Reduce overall core costs through recycling / reuse

- Reduce the envirionmental impact of your operations

- Cores kept in house and put back into production quickly

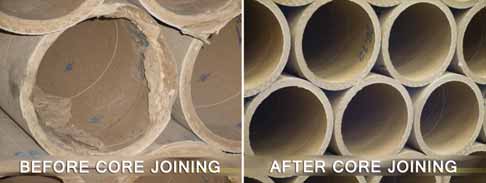

Each year the paper industry uses millions of cardboard and paper cores in their manufacturing process. Using Automatic Handling’s core joining system allows cores to be joined producing a clean edge as represented below. In addition to joining the cores, Automatic Handling can automatically store them until they can be reintroduced into your production line.

Why Implement Core Joining?

Every year the paper industry uses millions of cardboard and paper cores during the papermaking process. These cardboard tubes come in all different sizes and of different grades. In a typical parent core handling system for the Tissue Industry, these cores can weigh in at 100 pounds with a 16-inch diameter and each of these industrial-strength cardboard cylinders can carry a parent roll of paper up to 30 feet in circumference. Paper manufacturers reuse these cores repeatedly to avoid the high costs of disposal and replacement. Traditional methods of crushing, repulping, making board and cores are costly.

How It Works

Core Joining, Core Recycling, Core Splicing or Core Gluing are all similar terms to describe the process of removing the degraded or damaged portions of the paper cores and gluing or joining the remaining quality sections of the core back together. In many cases, the glued joints are stronger than the original when placed back into production. Deformed and damage core ends are just cut off, and the remaining healthy parts are joined together resulting in a quality core at a reduced cost. Although the Automatic Handling Core Joiner can work with multiple diameters of cores, the process of core joining is consistent.

- Core A is loaded into Core Joiner

- Core A leading deformed end is cutoff

- Core A trailing deformed end is cutoff and machined to a female cone

- Core B is loaded into Core Joiner

- Core B leading end is machined to male cone

- Adhesive is applied to Core B

- Core A and Core B are pressed together

- Cutting the new core to desired length

- Restart process using new core drop as new “Core A”

Are Recycled Cores Reliable?

Yes! Recycled cores perform just as well as new core because they: – Maintain their geometry (length, ID, and wall thickness) – Maintain their strength (crush and torque testing) – Do not have damaged ends and maintain their ability to properly chuck Paper Mill Core Recycling Recycling Cores saves energy, helps keep materials out of landfills and incinerators, and provides new cores for the production of new parent rolls. When waste cannot be prevented, recycling is the next best option. Core Recycling by Core Joining is more than extending the life of cores, conserving water, energy, land and raw materials – it is also about saving money. Automatic Handling’s patented system can reduce new core purchases by 80%.

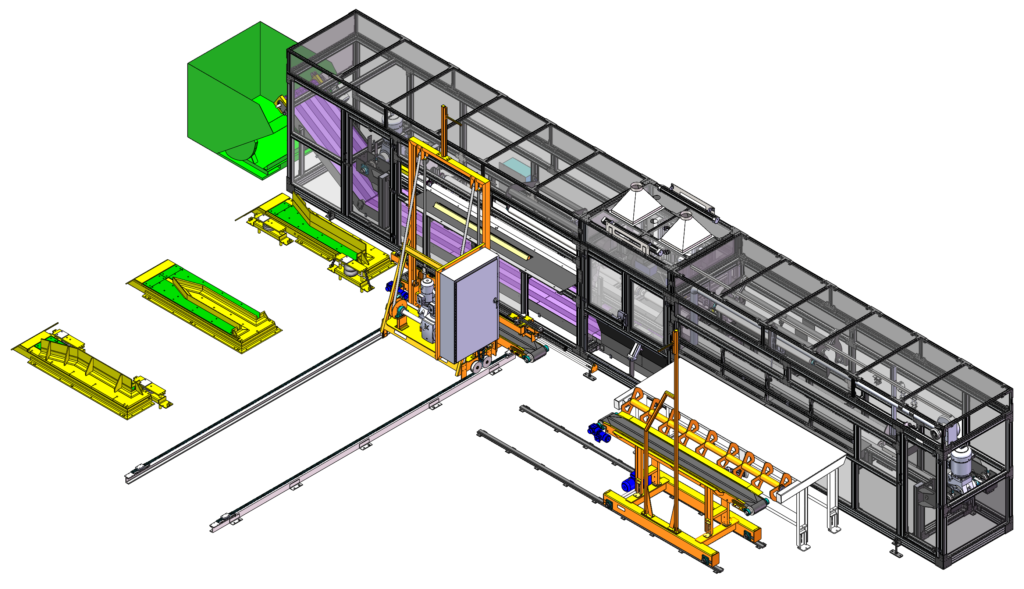

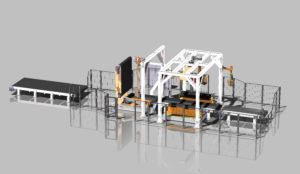

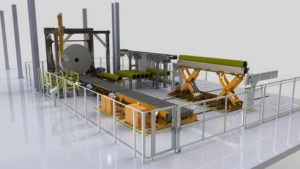

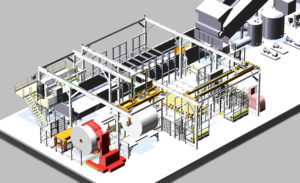

Core cutter / Joiner Example

This core cutter / core joiner demonstrates our capabilities through the following modules:

- Automatic load and unload of core bins

- Automatically cuts cores to programmed length

- Automatic creation of a joint

- Pre-progammed core length output requirements

- Fully integrated into Dry End

- Integrates into automatic core handling & storage systems

- Combines with AHI's Core Cleaning and Broke Handling System