Core Cleaning & Broke Handling Systems

Description

With fluctuating pulp prices every fiber counts. Automatic Handling’s patented Core Cleaning & Broke Handling System automates the processes of removing broke from spent rolls and reject parent rolls, accumulating the cores, and transferring broke to either a pulper or a baler. Add roll slabbing and pulper feed conveyors to optimize your pulp management and avoid wasted or unused fiber.

Applicable Industries:

Tissue & Towel

System Highlights

- Automatically remove slab broke from rejected cores or butt rolls

- Automatically cleans the core & prepares it for reuse

- Automatically charges the pulper or feeds the baler

- Integrates with Automated Core Storage & Retrieval

- Capable of Handling mulitple core widths and lengths

- Integrates with Automatic Guided Vehicles (AGV), the pulper and baler

- Automated integration of bins filled with cookies

Optimize your operations with Broke Handling

Flexibility and efficiency are the two key drivers of design when automating a broke handling system. Whether handling the wet end of the paper machine or the dry end trim and broke, experience dictates that manufacturing operations needs to have flexibility. Automation and safety systems need to be designed to safely and efficiently manage broke material that is introduced from any point in the manufacturing or finishing process, along with the ability to introduce virgin bales. Handling systems are required to be able to flexible in volume, able to handle the small amounts of broke during threading or large tonnages required during sustained periods of operation.

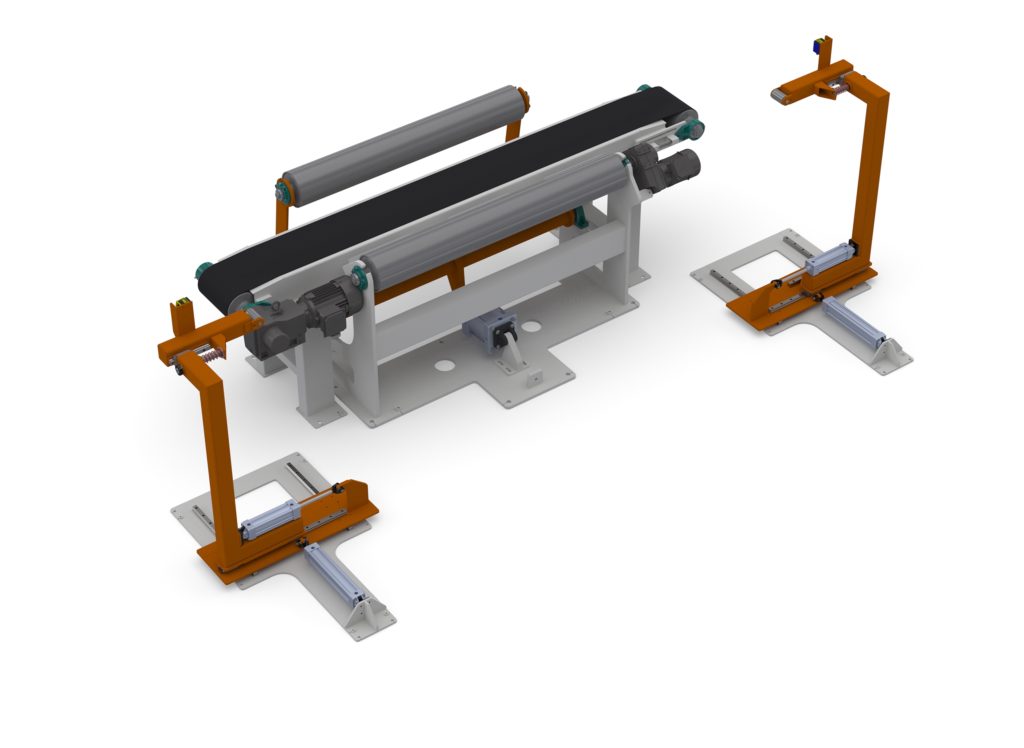

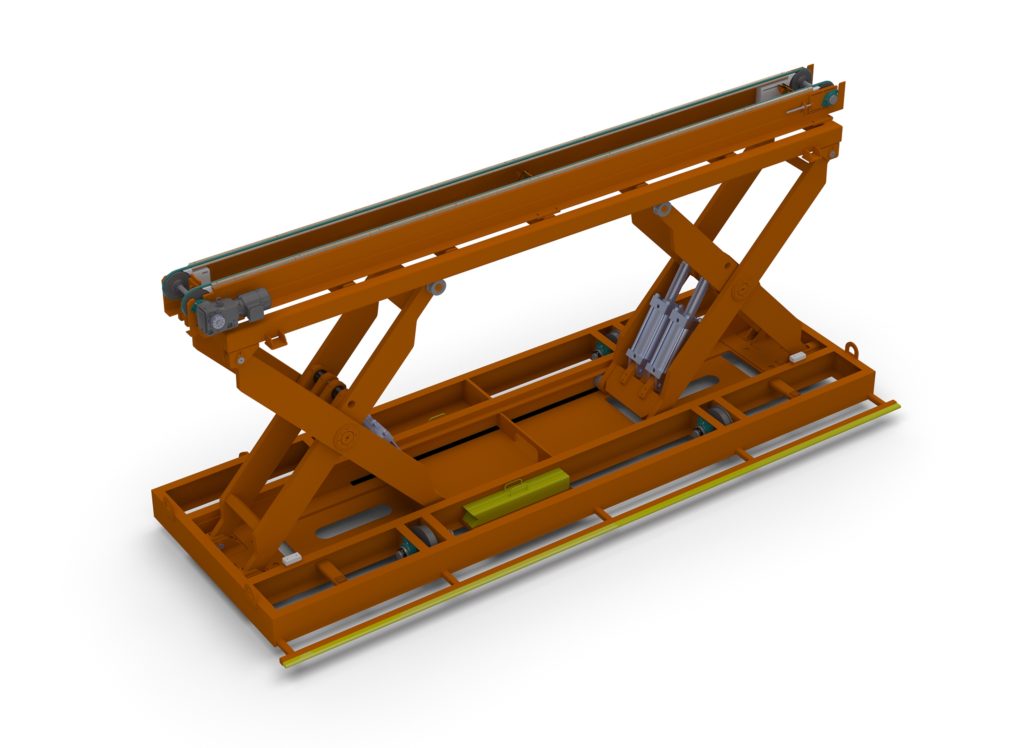

Pulper Feed Conveyors control the broke input

Modern high-efficiency pulpers are utilizing variable speed drives and high-efficiency rotors designed for maximum pumping. With these pulper processing technology improvements, it is essential to control the pulper infeed with intelligent conveyance controls to prevent overfeeding, fiber bundles and plugging. Some operations waste energy efficiency savings by over-feeding their pulper and increasing the output of their drives or sending wire contaminated bales into the pulper or delivering unbalanced recipes through the pulper.

Reduce fiber waste with Smart Roll Slabbing

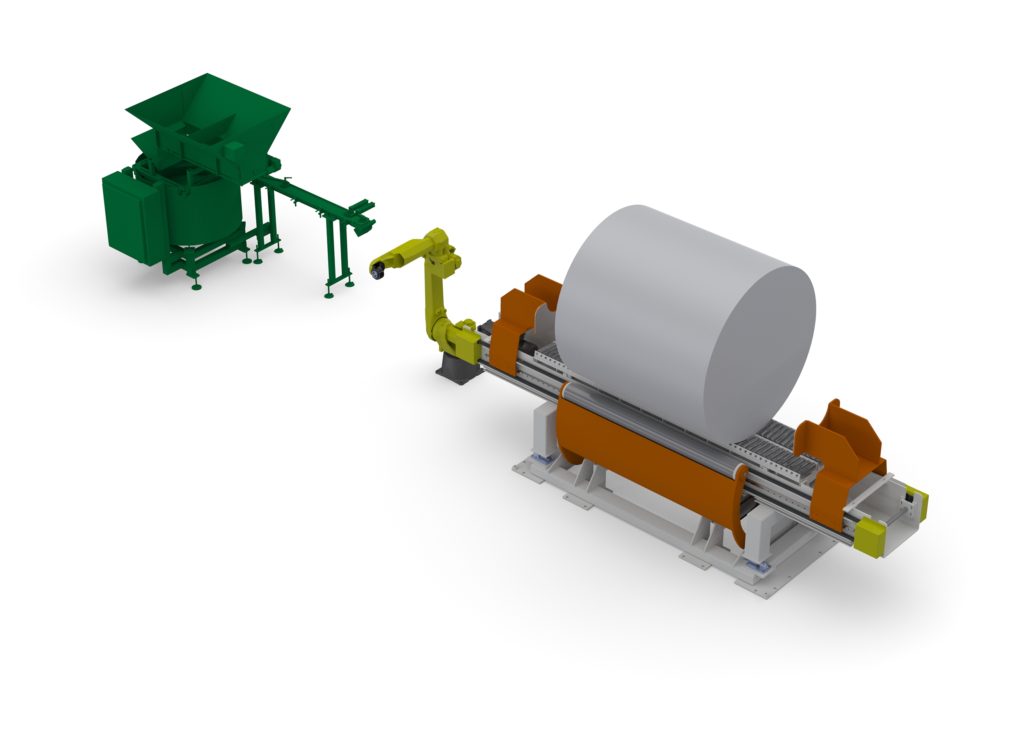

Part of our broke automation technology portfolio includes Smart Roll Slabbing and Core Cleaning to mechanically reclaim all fibers from rejected parent and spent rolls. Smart Slabbing is an over-the-conveyor or over-the-pulper apparatus design to remove measured amounts of fiber for efficient stock blending to achieve optimal feed rates. Spent rolls are introduced to the system from each converting line by fork truck, AGV or a system conveyor. The core buffer crane delivers the spent rolls either to a storage queue or directly to the core cleaning area. Spent rolls are slabbed down, cleaned, inspected, and automatically placed into core storage or core bins. If broke is not being accepted from either the pulper or the baler, the system accumulates and stores the spent rolls in the storage racks, where it can later be automatically retrieved and introduced back into the system for slabbing. Smart Roll Slabbing and Core Cleaning can be combined with automated product vision inspection technology to automate the rejection and storage of cores. Core Cleaning with Core Management and buffer systems can synergize the wet, the dry end, and converting operations into a highly efficient plant. When manufacturing and converting systems are correctly configured, there is no fiber waste.

Examples of Custom Core Cleaning & Broke Handling Systems we've built

Although the objective is the same, our team designs your system to accomplish the specific goals of your production operations.

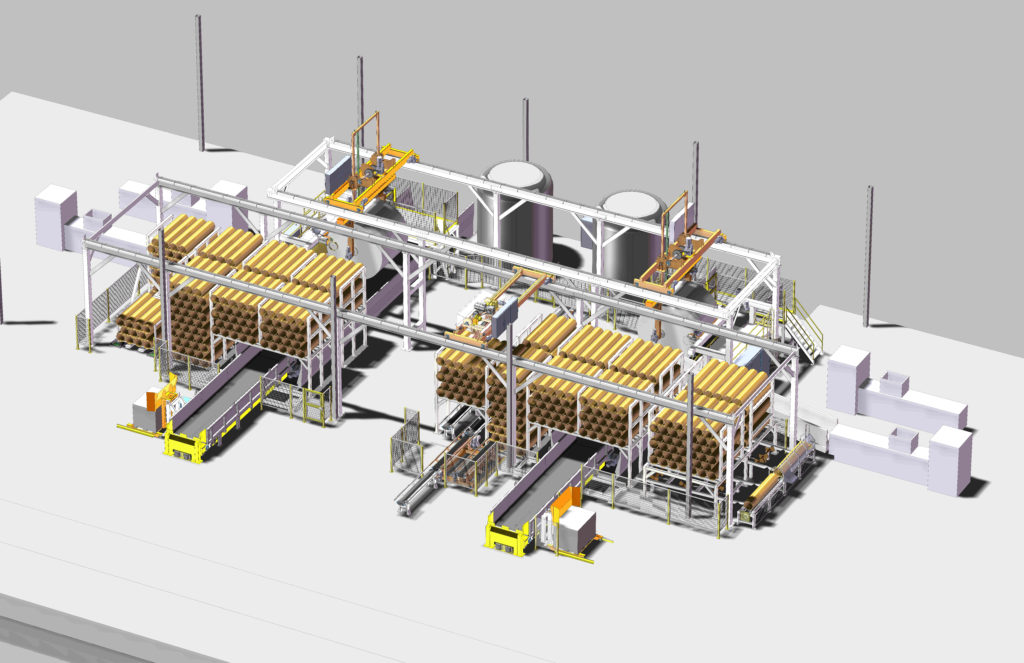

System Example 1

This is a newly built custom core cleaning and broke handling system. It includes modules such as:

- Fully automated core storage and retrieval

- Automatic Guided Vehicle (AGV) Interface

- Entire Automated Core Storage

- Automated Roll Slabbing

- Fully Custom Core Cleaning

- Fully automated core inspection

- Broke Handling & Pulper Feed

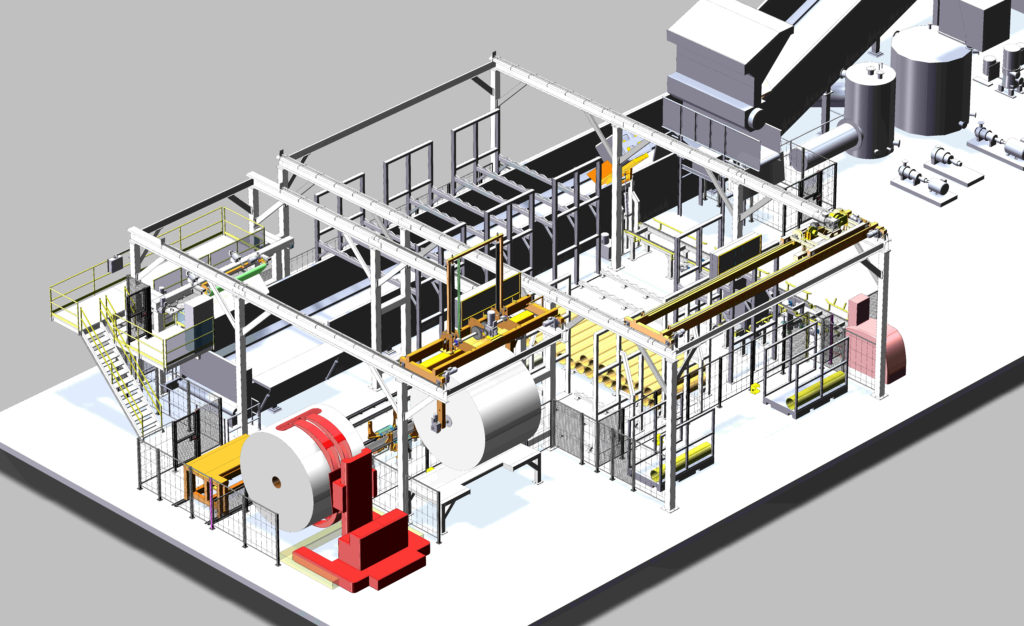

System Example 2

This custom core cleaning system is an enhancement to a client’s existing production line. This system includes:

- Roll Slabbing

- Automatic Guided Vehicle (AGV) Integration

- Integration into the client's existing operations

- Automatic Core Storage

Additional Core Management Equipment Examples

Automatic Handling manufactures a variety of core management equipment that can save you time and money by reusing and recycling cores.

Core plugging station

Core inspection station

Core lift carts